News

Rethinking Topology Optimization through Iterative Design Cycles with Pareto

Designing and manufacturing parts with a straightforward goal, for instance, to be lightweight and provide the greatest strength with available materials at a reasonable cost can be a fairly uncomplicated endeavor. Add a goal of improved heat transfer in a multiple load scenario and the complexity of the manufacturing challenge grows enormously, with the ability to design and evaluate parts becoming time- and cost-prohibitive.

In turn, this presents barriers to cycles of generative design which are opportunities for engineers to experiment and learn. With the limited ability to prototype using generative design cycles, engineers are constrained in the frequency of learning opportunities they have, along with the total number of iterations they can create. The result of these cost and time constraints can have negative impacts downstream in the manufacturing process.

Throughout this year, MITRE engineers were faced with the challenge of researching multi-objective optimizations and sought to find opportunities to enable MITRE to iterate and achieve optimal designs in a shorter time period and with reduced costs. Drawing upon a partnership facilitated by MITRE’s Bridging Innovation initiative with the Techstars Starburst Space Accelerator, MITRE’s engineers called upon Pareto™, a new software tool developed by SciArt Software.

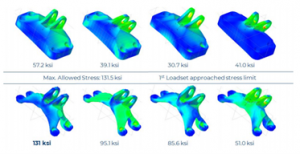

The optimization method employed by Pareto™ promises orders of magnitude improvement in speed of Finite Element Analysis (FEA) and topology optimization to provide viable design concepts for challenging problems. This new algorithm reduces the need for expensive, high power computing (HPC) and encourages design engineers to explore many ideas quickly at right at their desks.

Source: SciArt website, Pareto™: A new frontier for Generative Design January 4, 2019 brochure (PDF)

The potential of Pareto™ to conduct topology optimization at blazing fast speeds in comparison to competing software offerings while also resulting in more viable solutions was verified through multiple representative test runs by MITRE evaluating the software. Using a trial license from SciArt, MITRE found that Pareto™ delivered a significant improvement in calculation speed. Furthermore, the team verified that in all applicable cases, comparable models run on both Pareto™ and other optimization software provided similar geometries and were solved on the order of minutes and seconds. In one case, a beam problem was optimized for material volume reduction in under three minutes, compared to 39 minutes using a leading software competitor.

No longer will techniques to achieve multi-objective optimization have to be reserved for more mature designs or perceived high-value analyses. With Pareto™, MITRE engineers have been inspired to rethink the application and use of Finite Element Modeling (FEM) and topology optimization.

Examples of these applications are numerous: Pareto™ can enable quick initial feedback on thermal performance of a new computing system, generative design approaches to spacecraft design, and has inspired additional work considering real-time simulation applications such as the ability to validate the repurposing of a component on the fly using rapid FEM.

The ability to optimize components is not new in the industry, but completing highly complex optimization problems quickly while using low-cost computing resources is a game changer. MITRE’s government sponsors can now solve complex problems by rapidly experimenting though generative designs, from any location.